6PC 100g Bar Buffing Compound Kit

6PC Buffing Compound Kit Includes:

1PC 100g bar black emery buffing compound

1PC 100g bar general green buffing compound

1PC 100g bar white buffing compound

1PC 100g bar brown tripoli buffing compound

1PC 100g bar all-purpose blue buffing compound

1PC 100g bar red rouge buffing compound

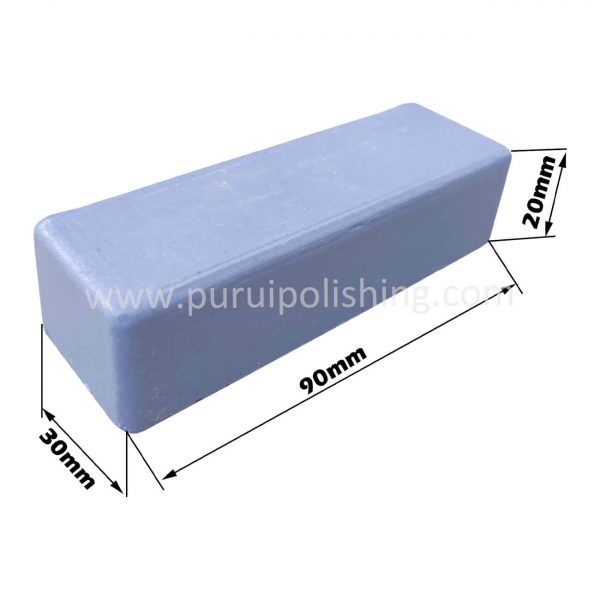

Size of the buffing compound:

Length*Width*Thickness(MM): 90*30*20

Packaging: White Box + carton + pallet (customized box is available)

MOQ: 200 sets

Categories: Metal Polishing Kit

Tags: Polishing Compound

- Description

- Inquiry

6PC 100g Bar Buffing Compound Kit:

• Complete buffing compound kit, from coarse to fine, meet most of your polishing needs

• Small size buffing compound kit, little money to get all 6 color buffing compounds

• Wide range of applications, used for polishing hard metals, soft metals, jewelry, plastic, wood and acrylic etc.

We also supply 6PC 4 oz Bar Polishing Compound Kit.

Application for each color buffing compound:

Black emery buffing compound: for first stage cutting of hard metals

General green buffing compound: for medium stage polishing of hard metals

White buffing compound: for final high polishing of hard metals

Brown tripoli buffing compound: for initial polishing of soft metals

All-purpose blue buffing compound: for final high polishing of soft metals

Red rouge buffing compound: for final high polishing of jewelry

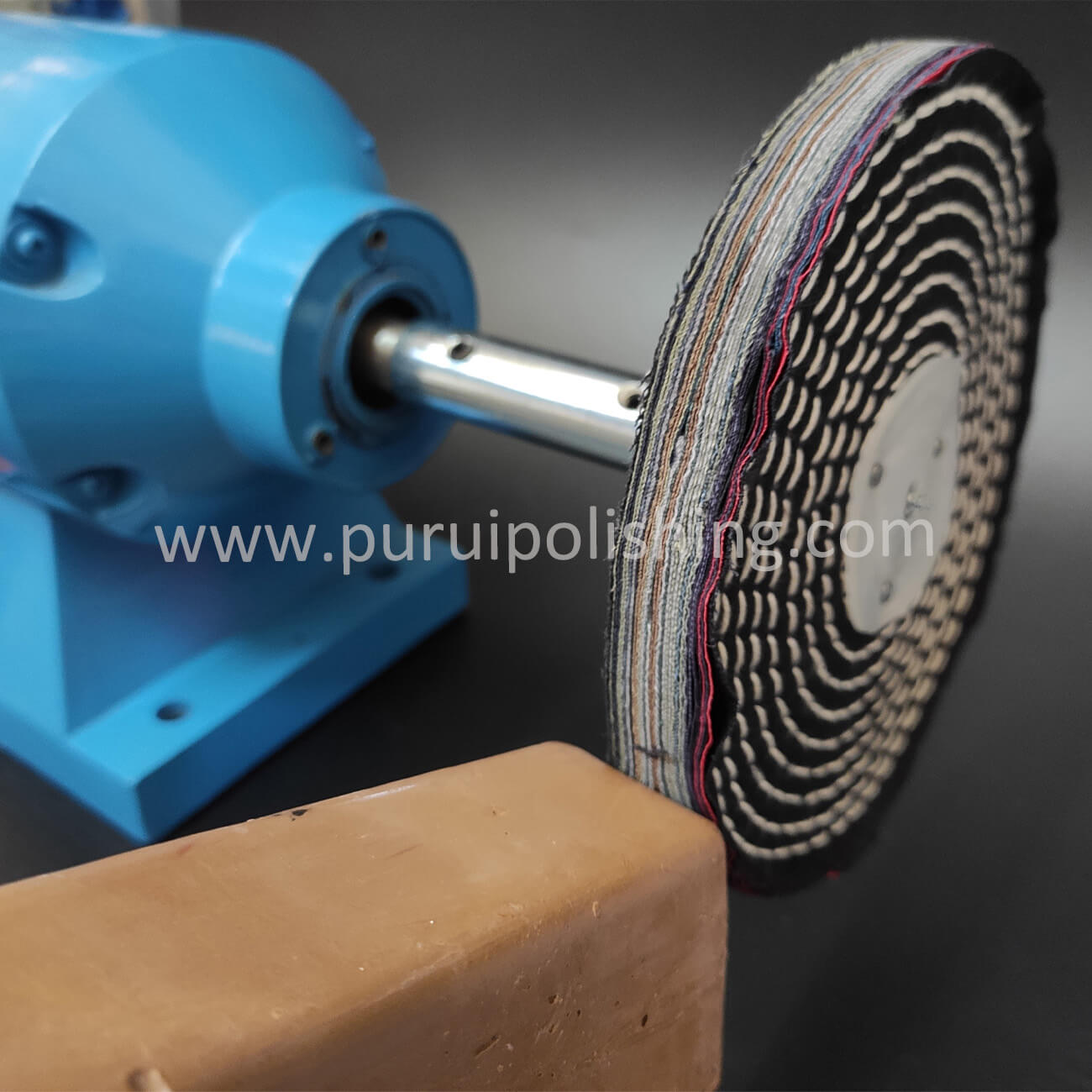

How To Use The Polishing Compound:

1. Choose the right polishing compound, please refer to our Buffing Compound Color Chart.

2. Attach the polishing buffing wheel to the bench grinder, drill, angle grinder or polisher.

3. Run the bench grinder, drill, angle grinder or polisher you used and apply the chosen polishing compound to the polishing buffing wheel for approx 2 seconds. The polishing compound is wax/abrasive based, so the motion of the spinning polishing buffing wheel generates heat which melts the wax/abrasive onto the polishing buffing wheel.

4. Apply the polishing buffing wheel to the item to be polished.

5. Apply more polishing compounds during polishing if required.

6. Change the polishing buffing wheel for the next polishing stage if needed, and repeat the process with a finer polishing compound. If you use the same polishing buffing wheel for different polishing stages, rake the polishing buffing wheel thoroughly and remove the previous polishing compound before changing from one compound to another.

Useful Polishing Tips:

1. Use compounds sparingly, black grease marks will appear on the workpiece if too much compound has been applied to the buffs. Remember little and often.

2. If it is possible, polish across marks and scratches not along them.

3. Use a different buff for each compound.

4. Do not mix different compounds on the same buff, Clean the buff off with a wire brush or buff rake before applying a different compound.

5. Attach the tapered mandrel to your drill, or angle grinder adapter to your angle grinder/polisher or bench grinder spindle adapter to your bench grinder and fix tightly.

6. Try to constantly vary the directions of which you polish. This is not always possible but recommended as some articles may be of an unsuitable size and shape.

7. If you are polishing small articles then you can fix your drill into a vice, this will enable you to polish these small articles with ease.

8. Sometimes when you have polished you may see a slight coat of black grease or finger marks on the workpiece, these can be removed with the microfibre cloth.

Protect polished articles with a good wax polish.

9. If you wish to Electroplate or lacquer to the polished article, make sure you use an as good degreaser and do not protect with a wax polish. Any dirt or grease or wax will interfere with the adhesion of the plated metal or lacquer.

Related Products

-

Read MoreQuick View

Read MoreQuick View20 Pack Zirconia Flap Disc Wheel Kit 4.5 Inch x 7/8 Inch T29 With 40/60/80 And 120# Grit

20 Pack 4.5 Inch Zirconia Flap Disc Wheel Kit:

Material: Zirconia alumina

Size: 4.5 Inch x 7/8 Inch inner hole

Type: T29

Kit includes:

10 pcs 40# grit

5 pcs 60# grit

3 pcs 80# grit

2 pcs 120# grit

-

Read MoreQuick View

Read MoreQuick ViewRed Rouge Polishing Compound For Jewelry

Material: Mineral oil, Plant lipide, Iron oxide red abrasive, Iron oxide black abrasive

Available size: 30g/50g/100g/120g/250g/500g/750g/1000g bar

Packaging: Shrink-wrapped + carton

-

Read MoreQuick View

Read MoreQuick View6PC 4 oz Bar Polishing Compound Kit

6PC Polishing Compound Kit Includes:

1PC 4 oz bar black emery buffing compound

1PC 4 oz bar general green buffing compound

1PC 4 oz bar white buffing compound

1PC 4 oz bar brown tripoli buffing compound

1PC 4 oz bar all-purpose blue buffing compound

1PC 4 oz bar red rouge buffing compound

Size of the polishing compound:

Length*Width*Thickness(MM): 118*28*22

Packaging: White Box + carton + pallet (customized box is available)

MOQ: 200 sets

-

Read MoreQuick View

Read MoreQuick View20 Pack Aluminum Oxide Abrasive Flap Disc Kit 4.5 Inch x 7/8 Inch T27 With 40/60/80 And 120# Grit

20 Pack 4.5 Inch Aluminum Oxide Abrasive Flap Disc Kit:

Material: Aluminium oxide

Size: 4.5 Inch x 7/8 Inch inner hole

Type: T27

Kit includes:

10 pcs 40# grit

5 pcs 60# grit

3 pcs 80# grit

2 pcs 120# grit

-

Read MoreQuick View

Read MoreQuick View11PC 6 Inch Polishing Kit For Bench Grinder

Polishing Kit Includes:

1PC 6 Inch x 1/2 Inch sisal buffing wheel

1PC 6 Inch x 1/2 Inch colour stitched cotton buffing wheel

1PC 6 Inch x 1/2 Inch loose-leaf cotton buffing wheel

1PC 1/2 Inch left hand bench grinder spindle

1PC 1/2 Inch right hand bench grinder spindle

1PC 100g bar black buffing compound

1PC 100g bar green buffing compound

1PC 100g bar white buffing compound

1PC 100g bar brown tripoli buffing compound

1PC 100g bar all-purpose blue buffing compound

1PC 40*40cm blue microfibre cleaning cloth

-

Read MoreQuick View

Read MoreQuick View10 PCS 6 Inch Angle Grinder Polishing Kit with M14 Adapter

This angle grinder polishing kit includes the following:

1PC 6 Inch x 1/2 Inch sisal buffing wheel.

1PC 6 Inch x 1/2 Inch colour stitched cotton buffing wheel.

1PC 6 Inch x 1/2 Inch loose-leaf cotton buffing wheel.

1PC 100g bar black buffing compound.

1PC 100g bar green buffing compound.

1PC 100g bar white buffing compound.

1PC 100g bar brown tripoli buffing compound.

1PC 100g bar blue buffing compound.

1PC M14 angle grinder spindle adapter.

1PC 40*40CM blue microfibre cleaning cloth.

-

Read MoreQuick View

Read MoreQuick ViewBlack Emery Polishing Compound

Material: Mineral oil, Plant lipide, Black corundum abrasive

Available size: 30g/50g/100g/120g/250g/500g/750g/1000g bar

Packaging: Shrink-wrapped + carton

-

Read MoreQuick View

Read MoreQuick View11PC 8 Inch Metal Polishing Kit for Bench Grinder

Metal Polishing Kit Includes:

1PC 8 Inch x 1 Inch sisal buffing wheel

1PC 8 Inch x 1 Inch colour stitched cotton buffing wheel

1PC 8 Inch x 1 Inch loose-leaf cotton buffing wheel

1PC 5/8 Inch left hand bench grinder spindle

1PC 5/8 Inch right hand bench grinder spindle

1PC 100g bar black buffing compound

1PC 100g bar green buffing compound

1PC 100g bar white buffing compound

1PC 100g bar brown tripoli buffing compound

1PC 100g bar all-purpose blue buffing compound

1PC 40*40cm blue microfibre cleaning cloth

-

Read MoreQuick View

Read MoreQuick ViewAll-Purpose Blue Polishing Compound

Material: Mineral oil, Plant lipide, Aluminium Oxide abrasive

Available size: 30g/50g/100g/120g/250g/500g/750g/1000g bar

Packaging: Shrink-wrapped + carton

-

Read MoreQuick View

Read MoreQuick View10 PCS Abrasive Cartridge Rolls Kit with 3/32 Inch Shank

10 PCS Abrasive Cartridge Rolls Kit:

Material: Aluminum Oxide sandpaper

Kit Includes:

Each 2pc 240#/400#/600#

Each 1pc 800#/1000#/1500#/2000#

Sizes of the abrasive cartridge rolls:

Rolls Diameter: ≈12MM

Total Length: ≈58MM

Shank Size: 3/32 Inch