Related Posts

How to polish raw stainless steel?

How to polish raw stainless steel?

There are different ways to polish raw stainless steel to the mirror surface, but all these ways require three stages, including rough abrasive grinding stage, polishing stage and buffing stage. Here we have listed a way to polish raw…

Polishing Buffing Compound

Polishing Buffing Compound:

Polishing Buffing compounds are used with buffing and polishing wheels to increase the effectiveness of the wheel and to help you accomplish your tasks more quickly. The polishing buffing compounds are wax/abrasive based, they come in all different types and colors, each…

How To Clean Polishing Buffing Wheel?

How To Clean Polishing Buffing Wheel?

In the process of polishing items using a polishing buffing wheel, dirt cut from items and residual polishing compound will build up on the polishing buffing wheel, which will not only damage the items to be polished, but also…

How To Use Polishing Compound

How To Use Polishing Compound?

Polishing compound is also known as polishing paste, polishing wax, buffing compound. The polishing compound is made of abrasives, tallow, paraffin wax, etc. They are commonly made as solid bars and used with polishing buffing wheels to smooth metals, jewellery,…

How To Polish Aluminum To Mirror Finish?

How to polish aluminum to mirror finish:

Step 1—Prepping the surface

Clean and degrease the item you want to polish, make sure the surface is free of dirt. If the surface of the workpiece is lacquered you must remove the lacquer.

Step 2—Sanding

If the parts are heavily…

How To Use Buffing Wheel?

How To Use Buffing Wheel?

First step: Choose the equipment for buffing wheel, such as bench grinder, polishing machine, drill, sand polisher, etc… The following describes how the buffing wheel works on some equipment:

1. Bench Grinder

There are two options for using the buffing wheel on bench…

Rotate Speed for Polishing And Buffing

Rotate Speed for Polishing And Buffing:

The correct peripheral rotate speed is an important consideration in getting the right results from your buffing operation. Working at high rate will heats the work surface and prevents the polishing compound working properly, while working at low speed…

Equipment And Supplies Needed For Polishing

Equipment And Supplies Needed For Polishing

If you want to polishing a material, some necessary equipment and supplies are needed.

Equipment

Equipment can be used for polishing include polishing/buffing machine, bench grinder, sander grinder/polisher, drill and rotary tool. The rotate speed recommended for polishing & buffing is…

PURUI Polishing Products

Welcome to visit our wevsite.

We are focus on the professional polishing solution.

We supplier kinds of high-quality polishing products.

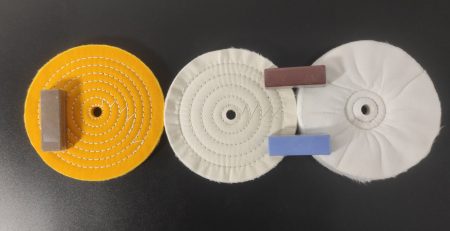

Buffing Compound Color Chart

The following picture will tell you how to choose polishing wheel and polishing compound when polishing different material objects.

read more