WHAT IS BUFFING COMPOUND?

Buffing compound is a mixture. It consists of mineral oil, plant lipide and abrasive. Buffing compound has different colors and sizes. It generally be used with a buffing wheel together to polish different materials for getting a fine surface or mirror surface. Using the buffing compound can promote your polishing efficiency.

WHAT COLORS DOES THE BUFFING COMPOUND HAVE?

PURUI POLISHING’s buffing compounds have 8 colors. Grey, black emery, general green, white, brown tripoli, all-purpose blue, red rouge and chrome pink.. The different colors are used for different usages.

WHAT ARE BUFFING COMPOUNDS MADE OF?

The buffing compounds are made of mineral oil, plant lipide and abrasives. The difference between each color compound is the abrasive and the fineness of the abrasive. The brown Tripoli uses the brown corundum abrasive. The all-purpose blue uses the aluminum oxide abrasive. The black emery uses the black corundum. The general green uses the aluminum oxide abrasive and the chromium oxide green abrasive. The white uses the aluminum oxide abrasive. The chrome pink uses the aluminum oxide abrasive. The red rouge uses the iron oxide red abrasive and the iron oxide black abrasive.

The production process of the buffing compound is as follows. Mix the materials at the ratio of each composition first. Then stir the mixture and make it uniform. Heat the mixture to the given temperature and put the mixture into the mould by weight. Cooling the mixture in the water. Finally, take the mixture out from the mould and then we get the buffing compound.

AVAILABLE TYPE AND SIZE OF THE BUFFING COMPOUND?

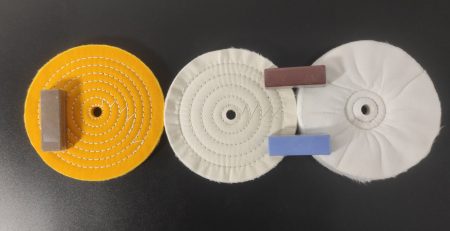

We have 2 types of the buffing compound, the one is buffing compound bar and another is buffing compound stick. The compound bar is packaged with hot shrink film and carton. The compound stick is packaged with brown paper + plastic tube + carton. Pictures for both buffing compounds are as below:

Available size of the buffing compound bar: 50g, 100g, 120g, 250g, 500g, 750g, 1000g bar.

Available size of the buffing compound stick: 50g and 100g.

The details please review our buffing compound page.

WHAT DO THE COLORS OF BUFFING COMPOUND MEAN?

Different color buffing compound for different purpose. Some compounds are used for rough cutting, some are used for initial polishing, some are used for final buffing and some are used for polishing special material. Below we will break down each color buffing compound in detail, after that you can choose the buffing compound easily.

Grey buffing compound

Grey buffing compound is designed as a heavy duty cutting compound. This compound has a coarse grin abrasive. It’s very aggressive and efficiency. Great for first cutting on stainless steel to remove the large scratches, marks and rusts. Also can be used on other metals, such as steel, iron, aluminum alloy, bronze, brass, copper, etc.

Recommended use with sisal buffing wheel or hard treated buffing wheel.

Black emery buffing compound

For first stage cutting and flattening on stainless steel and steel, iron etc. The purpose is to remove the deep scratches, marks, rusts, corrosions from the surface of the workpiece. To prepare the surface for next stage polishing. Black emery buffing compound also called as stainless steel polishing compound. It’s great for polishing stainless steel.

Recommended use with sisal buffing wheel and hard treated buffing wheel.

General green buffing compound

For middle stage polishing on stainless steel, steel and iron etc. The purpose is to refine the surface from the first stage polishing result and do preparation for the final finishing. To get a wonderful final results, this step is very necessary.

Green buffing compound can be used with sisal buffing wheel and stitched cotton buffing wheel.

White buffing compound

For final stage finishing on stainless steel, steel and iron etc. The purpose is let your workpiece get a perfect mirror surface.

White buffing compound work well with cotton buffing wheel and flannel buffing wheel.

Brown Tripoli buffing compound

For initial stage polishing of soft metals, such as aluminum, bronze, brass, copper, silver and gold etc. The purpose is remove the light scratches, marks, spots and flattening the surface. Brown tripoli compound is the best compound for aluminum and soft metals.

This compound is work well with sisal buffing wheel, stitched cotton buffing wheel and treated cotton buffing wheel.

All-purpose blue buffing compound

All-purpose blue buffing compound are mainly used for final finish on soft metals, such as aluminum, bronze, brass, copper, silver and gold etc. This buffing compound also can use to polish plastic, resin, acrylic etc. The purpose is let your workpiece get a wonderful shine surface.

Recommended use with cotton buffing wheel and flannel buffing wheel.

Red rouge buffing compound

Red rouge buffing compound is designed for polishing precious metals, such as platinum, silver and gold etc. This compound is more grease and with micro abrasive grain. It can restore the natural color of the metal and make the jewelry sparkle.

Recommended use with the loose-leaf cotton buffing wheel and flannel buffing wheel.

Pink buffing compound

Pink buffing compound is used for high polishing of chrome, nickel and other hard metals. Work well with cotton buffing wheels.

Below is a buffing wheels and buffing compounds color chart. It will help you to quickly to choose out the suitable buffing wheel and buffing compound for your work.

| Materials to be polished | Silver Golds & thin plates |

Nickel & Chrome Plating | Bronze Brass Copper Aluminum Pot & Soft Metals |

Steel & Iron | Stainless Steel | ||||||||||

| Polishing stage | Rough Stage | Initial Polishing | Final Buffing | Rough Stage | Initial Polishing | Final Buffing | Rough Stage | Initial Polishing | Final Buffing | Rough Stage | Initial Polishing | Final Buffing | Rough Stage | Initial Polishing | Final Buffing |

| Buffing Wheels | |||||||||||||||

| Sisal | X | X | X | ||||||||||||

| Spiral sewn | X | X | X | X | |||||||||||

| Loose | X | X | X | ||||||||||||

| Canton flannel | X | X | X | X | X | ||||||||||

| Buffing Compounds | |||||||||||||||

| Grey | X | X | X | ||||||||||||

| Black | X | X | X | ||||||||||||

| Brown | X | X | |||||||||||||

| White | X | X | |||||||||||||

| Blue | X | X | X | X | X | ||||||||||

| Green | X | X | |||||||||||||

| Pink | X | ||||||||||||||

| Red | X | X | X | X | X | ||||||||||

Equipment And Supplies Needed For Polishing:

Before the polishing work, you need to prepare the motor, kinds of buffing wheels and polishing compounds. During the polishing process, different material of workpiece and polishing stage, you will use different buffing wheel and compound. If you just start your polishing work and have nothing supplies. You can check the polishing products on our Amazon online shop PR PURUI. You can get all the polishing materials to meet your polishing needs.

We offer below items on Amazon:

Bench grinder spindle adapter 1/2” or 5/8”. This can used to convert your bench grinder to a bench polisher. Cotton buffing wheels 6” and 8”. Metal polishing kit for bench grinder 6” and 8”. Buffing wheel with buffing compound kit 3”, 4”, 6” and 8”. Metal polishing kit for angle grinder, adapter size 5/8”-11. Aluminum polishing kit. 6PC 100g buffing compound kit and 500g buffing compound. Non-woven polishing wheel. 50PC felt bobs kit. Abrasive sandpaper rolls kit.

HOW TO USE THE BUFFING COMPOUND?

- Choose the right buffing compound.

- Attached the polishing buffing wheel to the bench grinder, drill, angle grinder or polisher.

- Run the bench grinder, drill, angle grinder or polisher you used, apply the chosen buffing compound to the polishing buffing wheel for approx 2 seconds. The buffing compound is wax/abrasive based, so the motion of the spinning polishing buffing wheel generates heat which melts the wax/abrasive onto the polishing buffing wheel.

- Apply the polishing buffing wheel to the item to be polished.

- Apply more buffing compound during polishing if required.

- Change the polishing buffing wheel for the next polishing stage if needed, and repeat the process with a finer buffing compound. If you use the same polishing buffing wheel for different polishing stages, rake the polishing buffing wheel thoroughly and remove the previous buffing compound before changing from one compound to another.

USEFUL POLISHING TIPS

- Use compounds sparingly, black grease marks will appear on the workpiece if too much compound has been applied to the buffs. Remember little and often.

- If it is possible, polish across marks and scratches not along them.

- Use a different buff for each compound.

- Do not mix different compounds on the same buff, Clean the buff off with a wire brush or buff rake before applying a different compound.

- Attach the tapered mandrel to your drill, or angle grinder adapter to your angle grinder/polisher or bench grinder spindle adapter to your bench grinder and fix tightly.

- Try to constantly vary the directions of which you polish. This is not always possible but recommended as some articles may be of an unsuitable size and shape.

- If you are polishing small articles then you can fix your drill into a vice, this will enable you to polish these small articles with ease.

- Sometimes when you have polished you may see a slight coat of black grease or finger marks on the workpiece, these can be removed with the microfibre cloth.

- Protect polished articles with a good wax polish.

- If you wish to electroplate or lacquer to the polished article, make sure you use an as good degreaser and do not protect with a wax polish. Any dirt or grease or wax will interfere with the adhesion of the plated metal or lacquer.