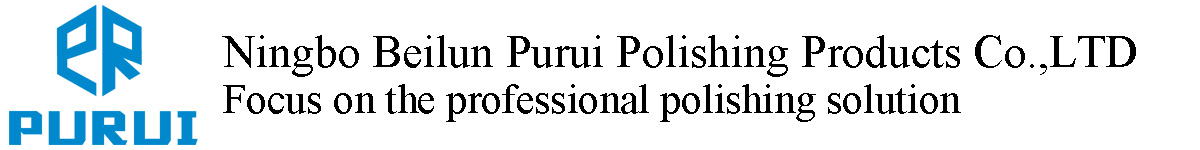

Abrasive Flap Wheel Emery Cloth Wheel

Abrasive: Aluminum Oxide

Available size:

Diameter*Thickness*Arbor hole

8″ X 2″ X 1″

10″ X 2″ X 1″

Grit: 80#-600#

MOQ: 30PCS each size and grit

Mixed Non Woven Abrasive Wheel with Sandpaper

Material: non woven cloth and aluminum oxide sandpaper

Color: Red

Available sizes are as follows:

Outer Diameter: 6″, 8″, 10″, 12″

Thickness: 25MM, 50MM

Arbor hole: 19MM

Sandpaper Grit: 180/240/320/400/600#

Aluminum Flap Disc with Fiberglass Backing

Abrasive: Aluminium oxide

Available Size (Outer diameter x arbor hole-Type):

50MM X 10MM -T27)

100MM X 5/8″-T27 or T29

115/125/150/180/230MM X 7/8″- T27or T29

Grit: 36#-600#

Satin Airway Buffing Wheel

Material: 7447 non woven cloth

Abrasive: Aluminium oxide

Diameter: 8″-16″

Thickness: 2Ply, 4Ply

Inner hole: 3″, 5″, 7″

For satin finishing and cleaning, removing rust, marks and scratches.

Can be with center plate or not.

White Nylon Fiber Grinding Wheel

Abrasive: Aluminium oxide

Available size:

Diameter: 100MM-400MM

Thickness: 10mm-100MM

Inner hole: As customized

Hardness: 4-12P

Grit: 60#-800#

MOQ: 100PCS each size and grit

Non Woven Polishing Wheel With Washer

Material: 7447 non woven cloth

Abrasive: Aluminium oxide

Diameter: 3″-12″

Thickness: 1Ply-6Ply

Arbor hole: Pin-hole, 1/2″, 5/8″

Calcined Alumina Oxide Flap Disc with Fiberglass Backing

Abrasive: Calcined alumina oxide

Available size (diameter*arbor hole):

50 X 10MM (T27)

100 X 16MM (T27)

115/125/150/180/230 X 22MM (T27 or T29)

Grit: 36#-120#

MOQ: 1000PCS each size and grit

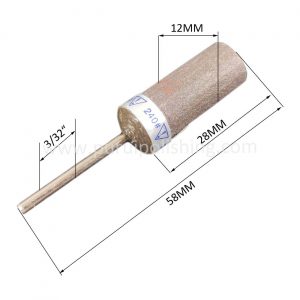

120MM Abrasive Flap Wheel Drum

Abrasive: Aluminum Oxide

Diameter: 120MM

Thickness: 100MM

Arbor Hole: 19MM

Grit: 40#-600#

MAX RPM: 4000

MOQ: 10PCS for each grit