29

Mar

How To Use Buffing Wheel?

First step: Choose the equipment for buffing wheel, such as bench grinder, polishing machine, drill, sand polisher, etc… The following describes how the buffing wheel works on some equipment:

1. Bench Grinder

There are two options for using the buffing wheel on bench…

read more

21

Apr

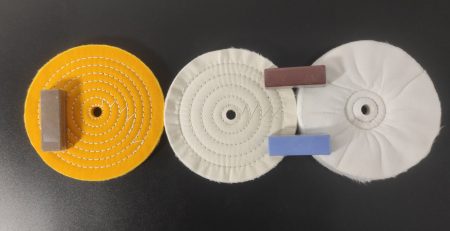

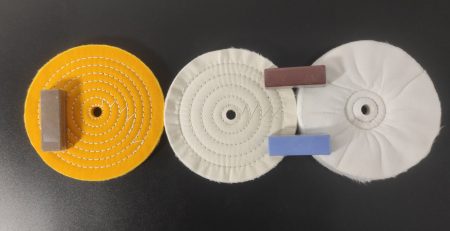

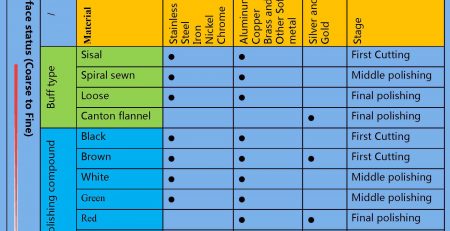

WHAT IS BUFFING COMPOUND?

Buffing compound is a mixture. It consists of mineral oil, plant lipide and abrasive. Buffing compound has different colors and sizes. It generally be used with a buffing wheel together to polish different materials for getting a fine surface or mirror…

read more

30

Mar

How to polish raw stainless steel?

There are different ways to polish raw stainless steel to the mirror surface, but all these ways require three stages, including rough abrasive grinding stage, polishing stage and buffing stage. Here we have listed a way to polish raw…

read more

31

Oct

Welcome to visit our website.

We are focused on professional polishing solutions.

We supplier kinds of high-quality polishing products.

read more

30

Oct

How to convert a bench grinder into a bench polisher?

Following is a guide to show you how to convert a bench grinder into a bench polisher:

Step 1 : Remove the outer guard from your bench grinder

Step 2: Remove the grinding stone from your bench grinder

Step…

read more

07

Jun

Rotate Speed for Polishing And Buffing:

The correct peripheral rotate speed is an important consideration in getting the right results from your buffing operation. Working at high rate will heats the work surface and prevents the polishing compound working properly, while working at low speed…

read more

04

Sep

What is polishing?

Polishing was sometimes known as finishing or buffing is the process of removing light scratches and abrasions from a surface, and creating the desired brightness of finish on that surface. It is the final stage in the surfacing process. When a material…

read more

30

Apr

How To Use Polishing Compound?

Polishing compound is also known as polishing paste, polishing wax, buffing compound. The polishing compound is made of abrasives, tallow, paraffin wax, etc. They are commonly made as solid bars and used with polishing buffing wheels to smooth metals, jewellery,…

read more

29

May

How To Clean Polishing Buffing Wheel?

In the process of polishing items using a polishing buffing wheel, dirt cut from items and residual polishing compound will build up on the polishing buffing wheel, which will not only damage the items to be polished, but also…

read more

05

Sep

How to polish aluminum to mirror finish:

Step 1—Prepping the surface

Clean and degrease the item you want to polish, make sure the surface is free of dirt. If the surface of the workpiece is lacquered you must remove the lacquer.

Step 2—Sanding

If the parts are heavily…

read more